University of Pittsburgh to play a lead role in new Department of Energy national institute focused on clean energy research

Swanson School of Engineering Chemical Engineering faculty will direct Natural Gas Upgrading Application Focus Area

PITTSBURGH (December 20, 2016) … In collaboration with the American Institute of Chemical Engineers (AIChE), the University of Pittsburgh’s Swanson School of Engineering will be part of a new institute that will leverage a total $70 million contribution by U.S. Department of Energy (DOE) as part of its new network of Manufacturing USA Institutes.

The Rapid Advancement in Process Intensification Deployment (RAPID) Manufacturing Institute, led by AIChE, is the 10th and newest member of this network, which received a five-year commitment from DOE and from private partners and energy industries. The goal is to increase domestic productivity and efficiency of various forms of energy by 20 percent over the next five years through improved manufacturing processes.

The RAPID proposal elected the University of Pittsburgh to serve as one of eight lead institutions in the RAPID organizational structure. The University is proposed to be responsible for strategic roadmapping and oversight on all research activity in RAPID’s Natural Gas Upgrading Application Focus Area. Pitt will guide and coordinate member efforts from the portion of 75 industrial partners, 34 academic institutions, seven national laboratories, two other government laboratories, and seven non-governmental organizations in the RAPID community who are targeting Natural Gas Research. The University will provide support through its multiple labs and centers dedicated to energy, process intensification, advanced manufacturing, simulation modeling, and leverage Swanson School faculty expertise in natural gas and unconventional fuels research.

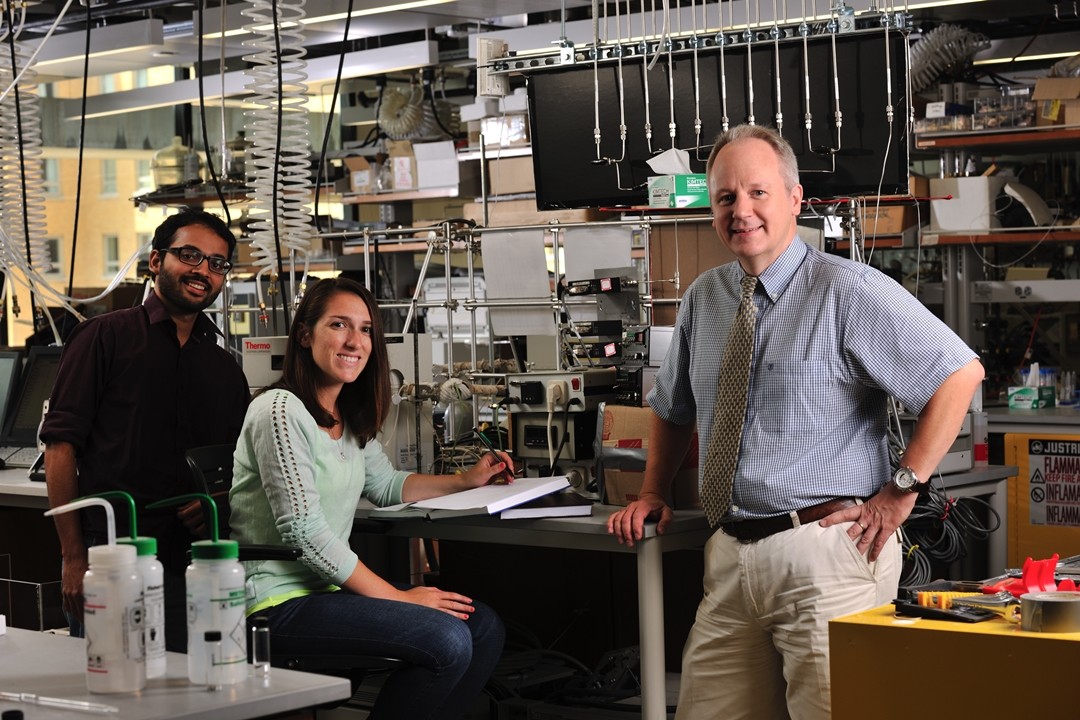

Heading up the Pitt team will be the Swanson School’s Department of Chemical and Petroleum Engineering under the direction of Michael Matuszewski, instructor and Director of External Relationships for Chemical and Petroleum Engineering, and Götz Veser, professor and Associate Director of Pitt’s Center for Energy.

“Creation of the RAPID Manufacturing Institute comes at a critical time as federal, university and industrial research are transforming how the U.S. improves its domestic energy production and use,” noted Mark Redfern, vice provost for research. “The Swanson School has more than a century of experience in energy research – and also established the first petroleum engineering program in the world – and so we are proud to partner with DOE and AIChE on this national challenge.”

According to Dr. Veser, the Pitt team will serve as the first tier of communication with the RAPID leadership in evaluating and recommending selection of natural gas-related projects. “Our focus is to identify more efficient and cost-effective methods to convert natural gas into clean energy and other useful products through advance manufacturing,” Dr. Veser said. “Access to Marcellus and Utica shale deposits has created new opportunities to utilize our natural resources in pursuit of greater independence, and the University of Pittsburgh is geographically located and technically positioned perfectly to lead the efforts towards clean and efficient utilization of these resources.”

In addition, the Pitt team said that its current industry partnerships help to provide a stronger connection to identifying potential end-uses, complement existing energy and manufacturing technologies, and even build a more knowledgeable workforce.

“The Swanson School’s partnership with industries such as Lubrizol Corporation – which is broad-based but includes a priority on process intensification research – reflects the mission of RAPID and the other Manufacturing Institutes to assure cooperation and to share approaches toward commercialization,” Matuszewski said. “Most importantly for Pitt, the RAPID framework will allow us to scale our existing collaboration model, almost instantaneously; we’ll be able to leverage the advances that RAPID supports to better train students with expertise in new technology approaches and the ability to engineer cutting-edge processes. Moreover, we will position all RAPID students to advance the U.S. workforce by invigorating it with advanced, environmentally-conscious expertise and increasing high tech job opportunities to further strengthen our country’s manufacturing industry.”

###

Contact: Paul Kovach